At Pittsburg Tank & Tower Group (PTTG), we engineer, fabricate, and build welded carbon steel tanks for the oil and water industries. Equipped with extensive experience in the design, manufacture, and maintenance of tanks, we have the knowledge and skills needed to deliver strong and durable tanks that fully meet the customer’s specifications.

We can produce welded tanks ranging in capacity from 50,000 gallons (1,200 bbl) to 10,000,000 gallons (240,000 bbl), which enables us to size a tank solution specifically to the project requirements and restrictions. Additionally, we offer various design options to further accommodate different customer needs, such as internal floating roofs (IFR’s), fixed, cone or dome roofs etc.

We offer a range of customizable carbon steel tanks that you can outfit with advanced monitoring systems to track liquid levels and temperatures. These features help maintain optimal performance and safety for critical applications.

Below, we provide a more comprehensive overview of our welded carbon steel tank capabilities. Additionally, we highlight the robustness of our tank designs and outline typical applications for our tank solutions.

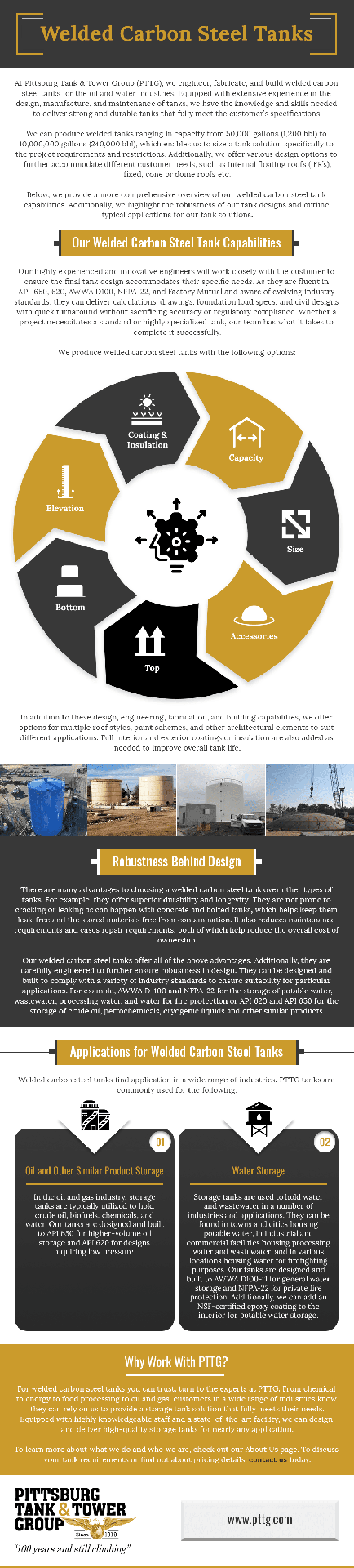

Our Welded Carbon Steel Tank Capabilities

Our highly experienced and innovative engineers will work closely with the customer to ensure the final tank design accommodates their specific needs. As they are fluent in API-650, 620, AWWA D100, NFPA-22, and Factory Mutual and aware of evolving industry standards, they can deliver calculations, drawings, foundation load specs, and civil designs with quick turnaround without sacrificing accuracy or regulatory compliance. Whether a project necessitates a standard or highly specialized tank, our team has what it takes to complete it successfully.

We produce welded carbon steel tanks with the following specifications:

-

Capacity: 50,000 gallons/1,200 bbl to 10,000,000 gallons/240,000 bbl

-

Size: any diameter and height

-

Accessories: IFR’s, Nozzles, internals, etc.

-

Top: open or closed

-

Bottom: flat or sloped

-

Elevation: ground or elevated

-

Coating & Insulation

In addition to these design, engineering, fabrication, and building capabilities, we offer options for multiple roof styles, paint schemes, and other architectural elements to suit different applications. Full interior and exterior coatings or insulation are also added as needed to improve overall tank life.

Robustness Behind Design

There are many advantages to choosing a welded carbon steel tank over other types of tanks. For example, they offer superior durability and longevity. They are not prone to cracking or leaking as can happen with concrete and bolted tanks, which helps keep them leak-free and the stored materials free from contamination. It also reduces maintenance requirements and eases repair requirements, both of which help reduce the overall cost of ownership.

Our welded carbon steel tanks offer all of the above advantages. Additionally, they are carefully engineered to further ensure robustness in design. They can be designed and built to comply with a variety of industry standards to ensure suitability for particular applications. For example, AWWA D-100 and NFPA-22 for the storage of potable water, wastewater, processing water, and water for fire protection or API 620 and API 650 for the storage of crude oil, petrochemicals, cryogenic liquids and other similar products.

Applications for Welded Carbon Steel Tanks

Welded carbon steel tanks find application in a wide range of industries. PTTG tanks are commonly used for the following:

Oil and other similar product storage

In the oil and gas industry, storage tanks are typically utilized to hold crude oil, biofuels, chemicals, and water. Our tanks are designed and built to API 650 for higher-volume oil storage and API 620 for designs requiring low pressure.

Water Storage

Storage tanks are used to hold water and wastewater in a number of industries and applications. They can be found in towns and cities housing potable water, in industrial and commercial facilities housing processing water and wastewater, and in various locations housing water for firefighting purposes. Our tanks are designed and built to AWWA D100-11 for general water storage and NFPA-22 for private fire protection. Additionally, we can add an NSF-certified epoxy coating to the interior for potable water storage.

Why Work With PTTG?

For welded steel tanks you can trust, turn to the experts at PTTG. From chemical to energy to food processing to oil and gas, customers in a wide range of industries know they can rely on us to provide a storage tank solution that fully meets their needs. Equipped with highly knowledgeable staff and a state-of-the-art facility, we can design and deliver high-quality storage tanks for nearly any application.

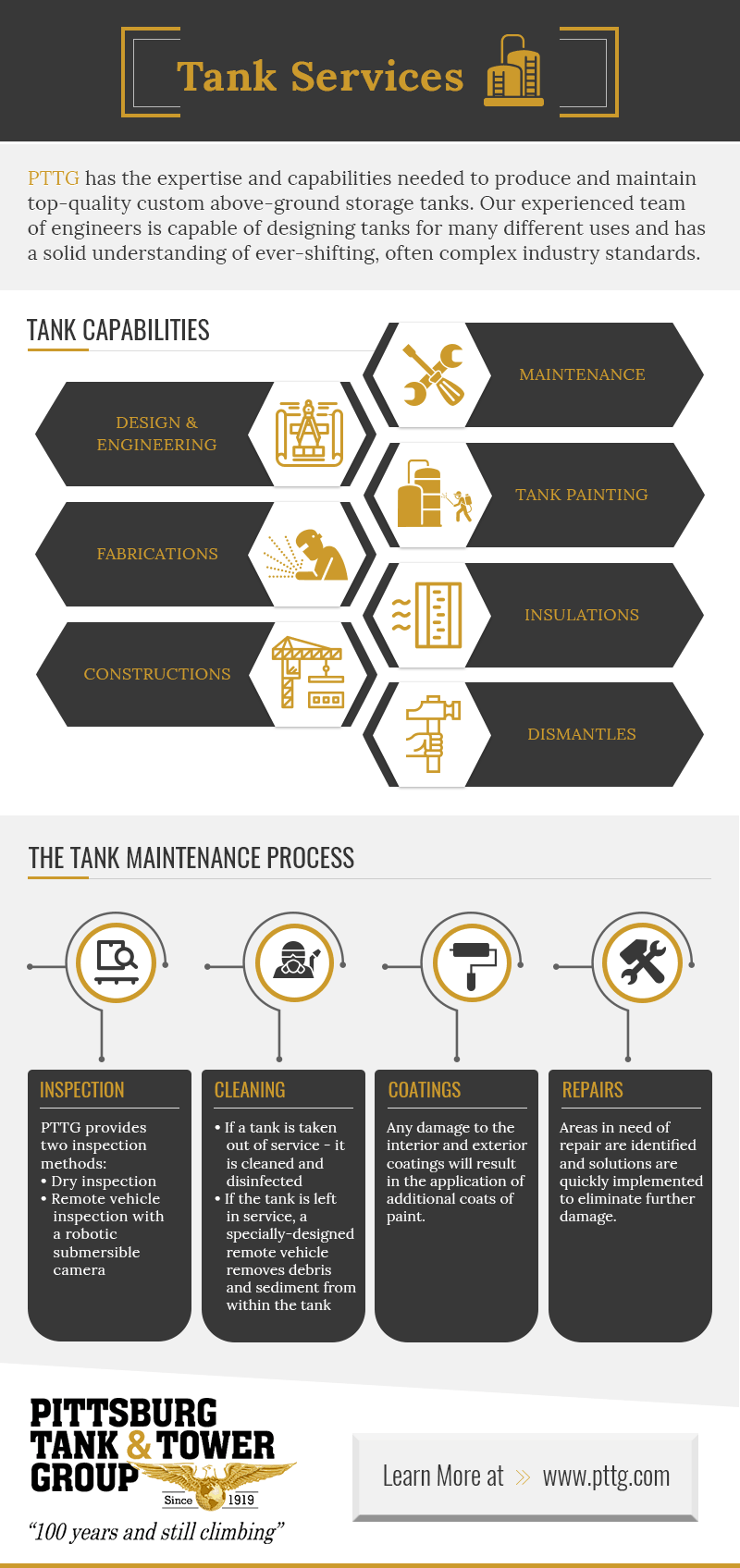

Our tank capabilities include:

Our highly skilled and fully certified welders create the tanks in the field from quality materials utilizing time-tested fabrication methods. We utilize advanced welding techniques to ensure our carbon steel tanks offer seamless joints and structural integrity. Our attention to detail means we can deliver high-quality standards for every tank and remain a trusted carbon steel tank manufacturer.

Our in-house painting team is fully trained in proper water tank cleaning and painting protocols. They employ OSHA-approved rigging and sandblasting and pressure water technology to clean tank interiors and exteriors safely and effectively.

Regular maintenance keeps tanks in proper working order throughout their expected service life as well as reduces overall operating and replacement costs. Our maintenance team provides all types of maintenance services for welded tanks varying in style, construction, and material.