With one of the largest paint rooms in the Midwest, and a plant designed for maximum safety and efficiency, the PTTG tank fabricating plant is a model of economy providing quality products delivered on time. Complete with CNC Plasma Cutter, rolling & forming equipment for material up to 2” thick, vertical wheelabrator, environmental controlled paint room 120’ x 90’ and 24 overhead cranes, our facility can meet your requirements. We fabricate carbon steel, stainless steel, Inconel, Monel, Hastelloy, AL-6XN, Duplex 2205 & 2304 and clad.

Learn More

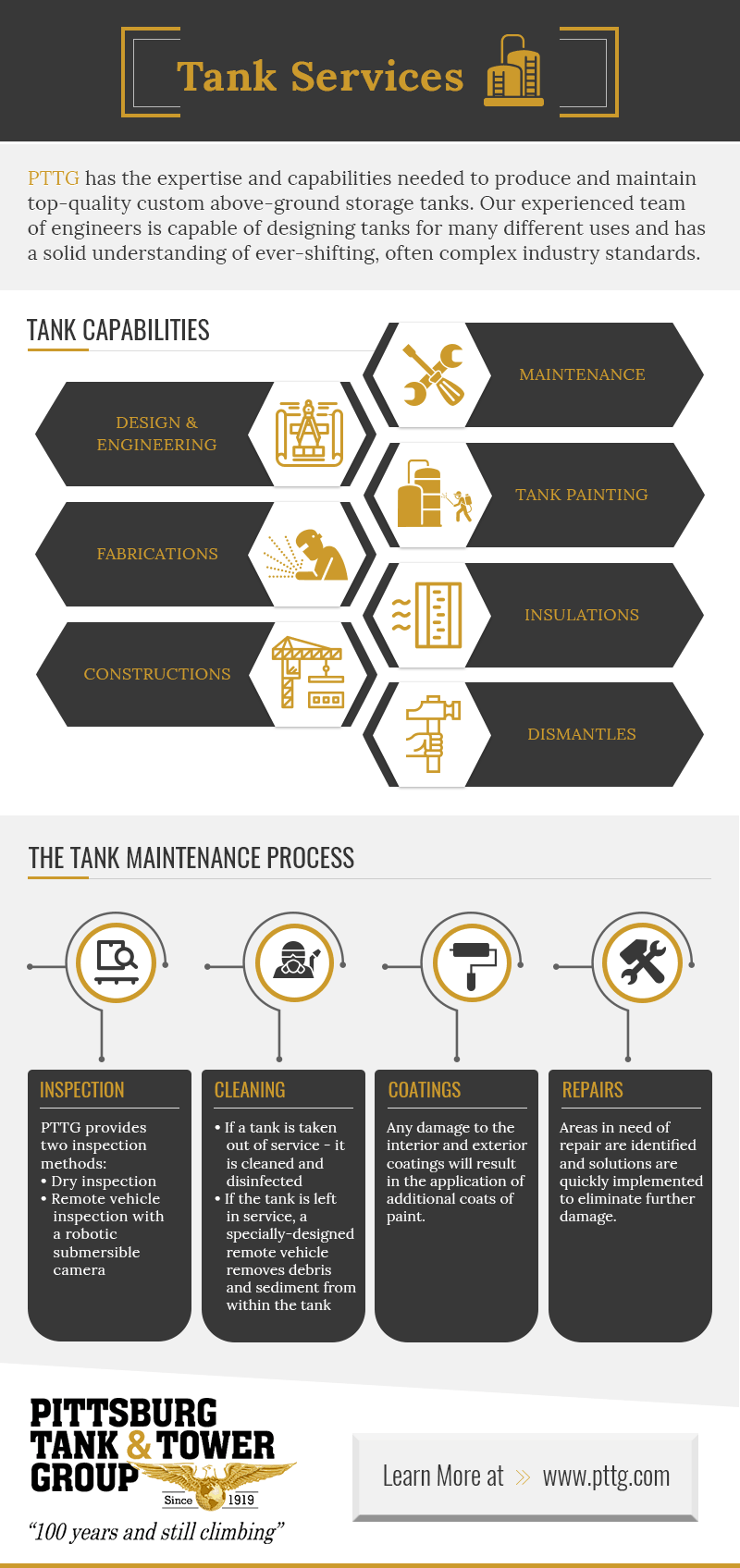

Pittsburg Tank & Tower Group has been providing reliable tank solutions since 1919. We provide quick and efficient tank fabrication and installation services throughout the year. To learn more about what PTTG offers, contact our experts today.

Shop Built

Shop BuiltBuilding on vast experiences with field erected tanks, PTTG can provide shop built tanks customized to particular needs and specifications. Shop tanks can conform to various standards, such as API, AWWA, NFPA, and Factory Mutual. They can range in size from 1,000 to 35,000 gallons, and PTTG can construct shop tanks of various materials, such as carbon, stainless and duplex steels. Full interior and exterior coatings or insulation can also be applied, as required. PTTG is also fully capable of delivering and installing new shop built tanks, as required.

Fabrication Specifications Quick View

Fabrication Specifications Quick ViewTypical Construction Materials:

-

Carbon steel

-

Special Alloys

-

Stainless Steel

Welding Processes:

-

Flux Cored Arc Welding

-

Gas Metal Arc Welding

-

Gas Tungsten Arc Welding

-

Submerged Arc Welding

-

Shielded Metal Arc Welding

Additional Equipment:

-

Air Compresses & Mobile

-

Automatic Vertical & Horizontal Welding Machines

-

Cranes

-

Diesel Generators

-

Mobile Equipment Trailers

-

Rigging & Fit-Up Euipment

-

Scaffolding

-

Submerged Arc Welding Equipment