The PTTG team of inspectors is equipped with state-of-the-art equipment, including laser range finders used to determine precise measurements and center of radiation levels, transits, tension-meters, digital dynamometers, UT equipment, Radman RF detectors, MEG test gear, tablets, digital cameras, and tablets with a web-based proprietary report software.

We now offer drone inspections with certified sUAS operators. Tower inspection is essential because it helps ensure the safety and stability of cell phone towers. These structures are often located in remote areas and can be difficult to access. That’s why it’s crucial to have a team of experienced professionals who can safely and efficiently inspect these towers.

How Does Communication Tower Inspection Work?

Our team of experts uses sophisticated tools and equipment to provide a proper communication tower analysis. For example, we use laser range finders to take precise measurements and identify the center of radiation levels.

We also use transits, tension meters, digital dynamometers, and UT equipment to conduct a thorough inspection. In addition, we use Radman RF detectors and MEG test gear to identify any potential problems.

According to OSHA, regular communication tower maintenance requires employees to climb very high heights- sometimes more than 1000 feet.

The two main types of communication tower inspections are:

-

Tower mapping is a critical part of any tower inspection. Our team uses the latest technology to create a detailed inspection report. It helps us identify potential problems and plan the best course of action.

-

Drone tower inspection is becoming increasingly popular. They offer a safe and efficient way to inspect these structures. Our team of certified sUAS operators can provide you with a detailed inspection report using the latest drone technology.

Both types of inspections are essential to ensure communication towers’ safety and stability.

The Importance of Communication Tower Inspection

Communication tower inspection is essential because it helps ensure the safety and stability of cell phone towers. These structures are often located in remote areas and can be difficult to access. That’s why it’s crucial to have a team of experienced professionals who can safely and efficiently inspect these towers.

Communication towers play a critical role in our lives. They enable us to stay connected with family, friends, and colleagues. They also provide vital communication services for businesses and organizations.

The following are some of the advantages of tower inspections:

-

It helps ensure the safety and stability of communication towers

-

Crucial to have a team of experienced professionals who can safely and efficiently inspect these towers

-

Use sophisticated tools and equipment when inspecting a communication tower properly

-

Identify potential problems and plan the best course of action

-

Provide a safe and efficient way to examine these structures

Market Scale notes that inspections of this sort allow for greater operational efficiency as they extend the lifespan of old buildings. In other words, you can avoid costly repairs and replacements by conducting regular inspections.

Communication tower inspection is a critical part of maintaining these structures. It’s essential to have a team of experienced professionals who can safely and efficiently inspect these towers. They can identify potential problems and plan the best course of action with the right tools and equipment.

That’s why it’s crucial to have a team of experienced professionals who can safely and efficiently inspect these towers. With the help of drone technology, we can now provide detailed drone communication tower inspection reports that help identify potential problems and plan the best course of action.

We’re the steel experts you can trust

Tower inspection is not something you should take lightly. It plays a vital role in ensuring the safety and stability of cell phone towers.

Pittsburg Tank & Tower Group is your one-stop shop for all your steel needs. We can design, build, and maintain substantial steel structures like tanks, communication towers, and support systems.

Our team of experts uses the latest technology and equipment to ensure the completion of your project safely and efficiently. If you’re curious about what we offer here at our company, don’t hesitate to contact us. We would be happy to chat with you and answer any questions you may have.

EIA/TIA Inspections

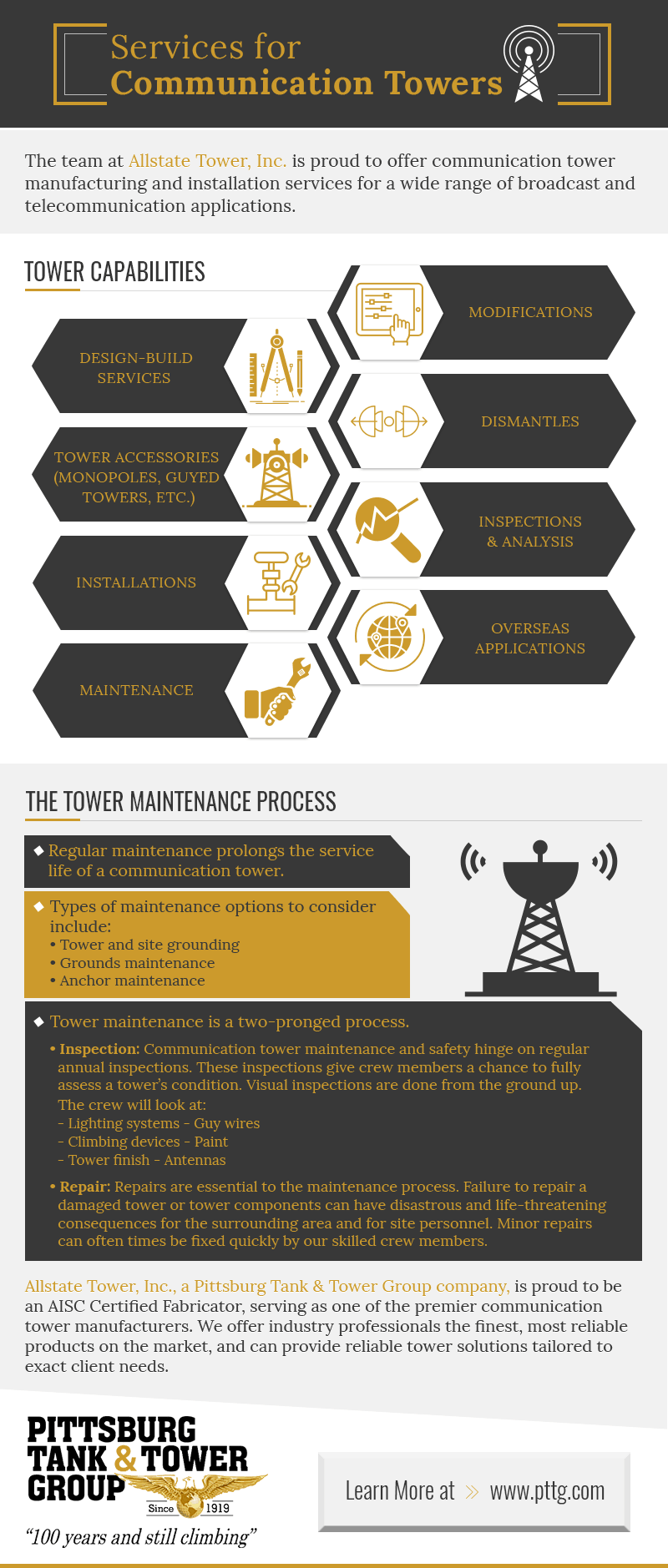

EIA/TIA InspectionsTowers are visually inspected for compliance with applicable EIA/TIA, OSHA, and FAA/FCC requirements.

Analysis

AnalysisA structure analysis ensures the tower does not exceed its designed capacity. We utilize drawings provided by the customer or our inspectors perform a site visit to collect the required data – guy wire sizes, antenna loading, member sizes, etc. Our team of engineers can provide suggested modifications upon request.

Ultrasound

UltrasoundProvides interior condition data of tubular towers to be used for an engineering analysis. Ultrasonic inspection reveals deficiencies that would not be found by a visual inspection. This technology allows for verification of metal thickness. This is critical on hollow tube structures to verify the current condition of the tower is as designed.

Sweep Testing

Sweep TestingSweep Testing is also known as VSWR (Voltage Standing Wave Ratio) which tests the power reflected from an antenna. This type of testing is used to align, troubleshoot, or make sure the antenna satisfies the bandwidth requirements specified.

Megger Testing

Megger TestingAdvanced clamp-on ground resistance testers are used to measure earth/ground resistance in multiple loop installations without disconnecting the ground.

Third Party Inspection

Third Party InspectionPost Modification/Third Party Inspection ensures a tower modification or “as built” site is installed in accordance to plans and specifications.

Troubleshooting Light System

Troubleshooting Light SystemOur experienced inspection team can troubleshoot and repair all major brands of light systems including incandescent, LED and medium intensity strobe systems.

Tower Mapping

Tower Mapping