Elevated water storage tanks are used to store water for fire protection and potable drinking water within a designated area or community. Elevated tanks allow the natural force of gravity to produce consistent water pressure throughout the system. Based on the intended application and needs of the distribution area, elevated water tank contractors can engineer these tanks with a wide range of shapes, sizes, and materials.

For more than 100 years, Pittsburg Tank & Tower Group (PTTG) has been a dedicated steel tank fabricator and provider of quality above-ground storage and elevated tanks for customers throughout the US. Our elevated storage tanks are engineered, manufactured, and constructed within American Water Works Association and National Fire Protection Association (AWWA and NFPA) guidelines, and are built to meet location-specific industry requirements and regulations.

Elevated Storage Tank Types

Elevated water storage tanks are typically manufactured by tank builders from carbon steel, which is inexpensive to form and exceptionally durable. Carbon steel is easy to maintain, and steel elevated tanks have been known to last up to 60 years. Below is a list of some of the most common tank designs.

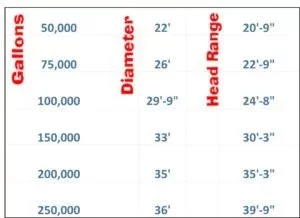

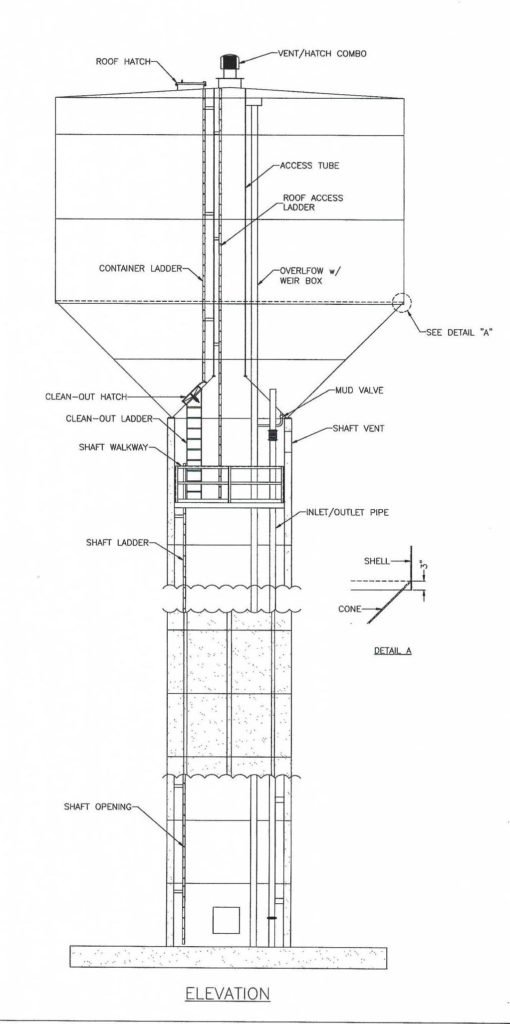

Mini Composite Elevated Tank

New patent pending technology in the elevated tank market, this CET style tank is comprised of a pre-cast concrete shaft and a cone and cylindrical wall steel container. Through this process, we can speed up on-site construction by pre-casting the concrete segments and assembling the tank at ground level resulting in expedient segmental only construction.

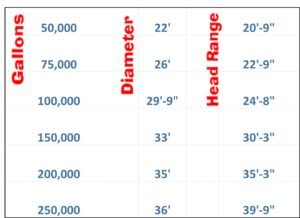

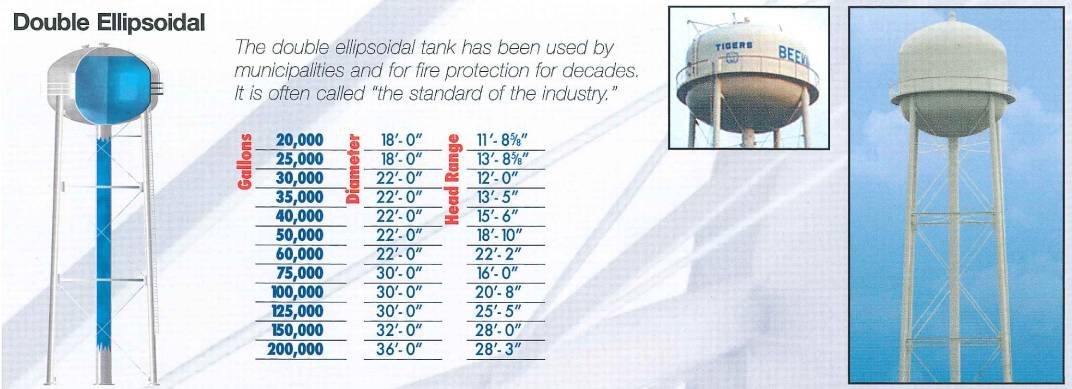

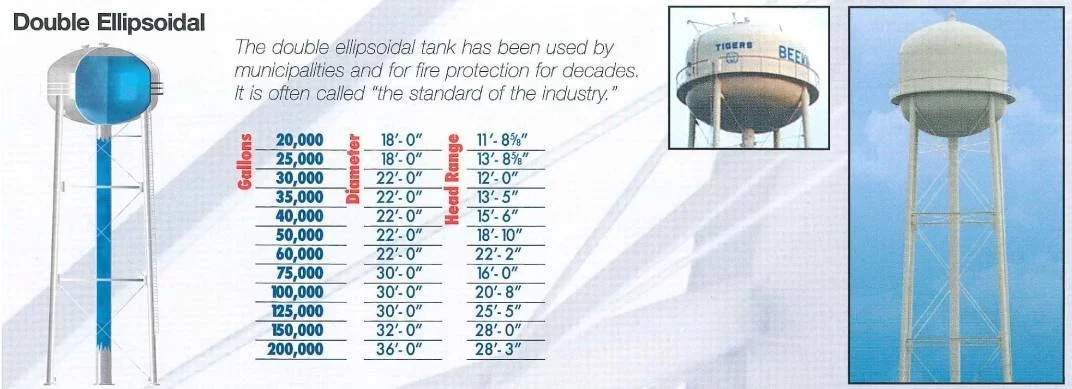

Constructed of a cylindrical side wall welded to an ellipsoid top and bottom and supported by steel beams and columns, double ellipsoidal storage tanks are often considered to be the standard tank style. At Pittsburg Tank & Tower, we offer the following double ellipsoidal storage tank sizes

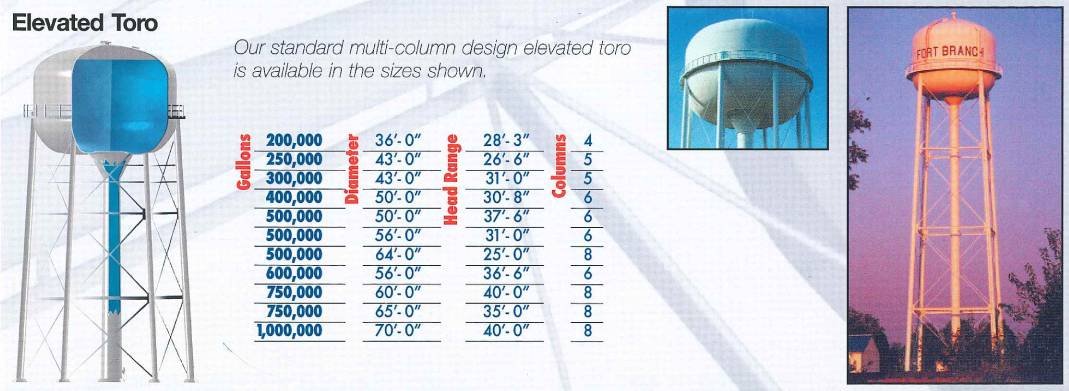

Elevated Toro

Elevated toro storage tanks are named for their torispherical tank design. These tanks are commonly used for particularly high pressure applications. Our elevated toro tanks are designed in a variety of sizes and column options

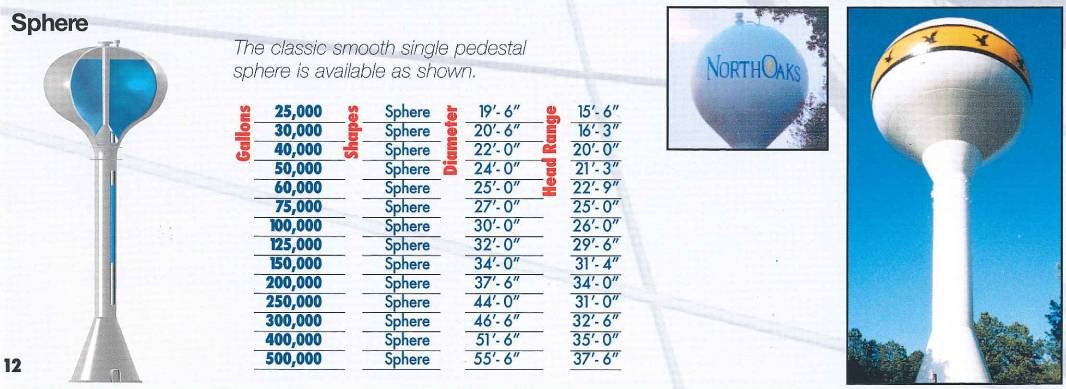

Sphere

Elevated spheroid water tanks are often popular for their sleek designs and aesthetic appeal. We offer a stable spheroid water tank mounted on a single-pedestal in the following dimensions

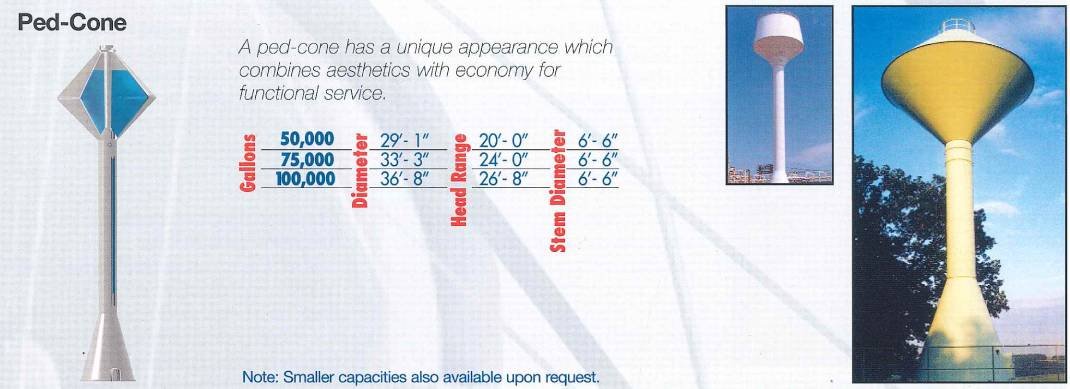

PED-Cone

PED-Cone tanks are notable for their unique appearance, with a single cone-shaped base supporting an elevated spherical tank. Our PED-Cone tanks are available in the following sizes

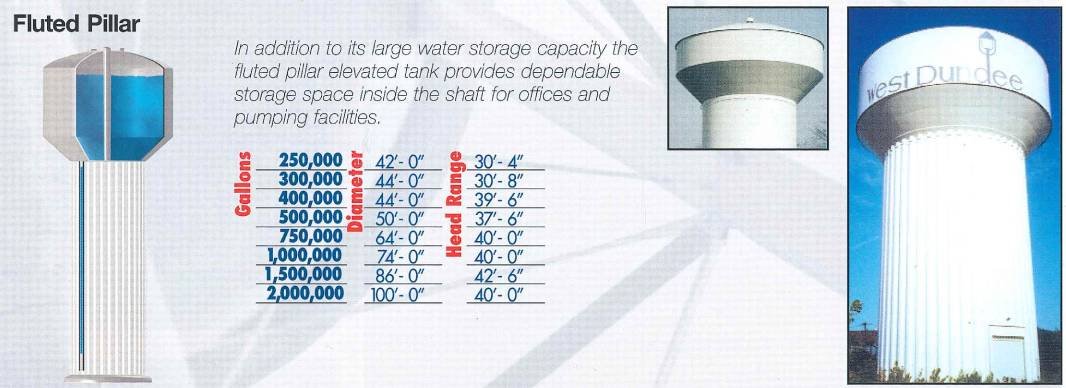

Fluted Pillar

Fluted pillar elevated tanks provide space within the fluted shaft for offices, storage, pump equipment, and more, as well as extensive water storage capacity. Available sizes include

B.E.S.T. Tanks

Low maintenance, incredibly safe environmental factors, and excellent relocation capabilities make this tank the BEST Tank. Bolted-Elevated-Storage-Tanks are factory applied, glass fused to steel tanks. The urethane sealant is specially designed for potable water service. Roof is maintenance-free glass fused to steel aluminum. The tower is hot-dipped galvanized steel. All together this provides the lowest maintenance elevated tank possible. PTTG support structures are designed and manufactured in accordance with applicable standards of AWWA & ASCE. Bolt-together factory galvanized sections allow for year-round construction and eliminates painting cost.

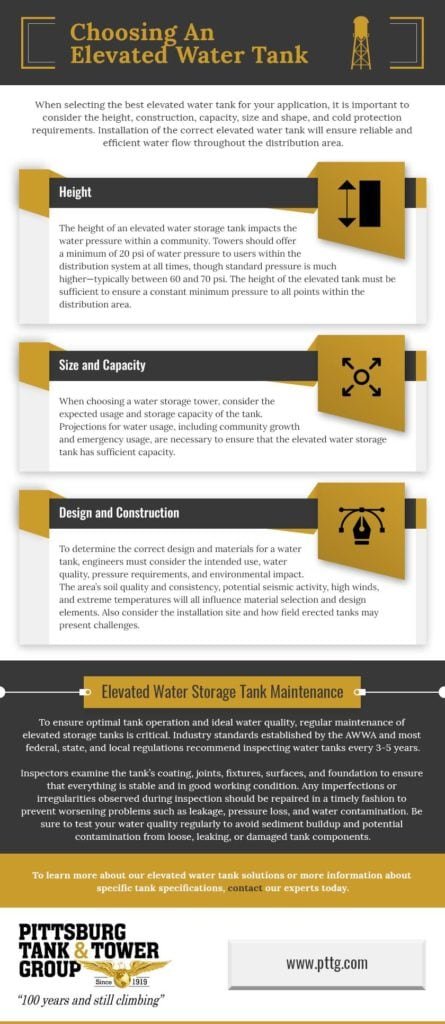

Choosing An Elevated Water Tank

When selecting the best elevated water tank for your application, it is important to consider the height, construction, capacity, size and shape, and cold protection requirements. Working with reputable water tank manufacturers for installation will ensure reliable and efficient water flow throughout the distribution area.

Height

The height of an elevated water storage tank impacts the water pressure within a community. Towers should offer a minimum of 20 psi of water pressure to users within the distribution system at all times, though standard pressure is much higher—typically between 60 and 70 psi. The height of the elevated tank must be sufficient to ensure a constant minimum pressure to all points within the distribution area.

Size and Capacity

When choosing a water storage tower, consider the expected usage and storage capacity of the tank. Projections for water usage, including community growth and emergency usage, are necessary to ensure the elevated water storage tank has sufficient capacity.

Design and Construction

To determine the correct design and materials for a job, elevated water tank contractors must consider the intended use, water quality, pressure requirements, and environmental impact. The area’s soil quality and consistency, potential seismic activity, high winds, and extreme temperatures will all influence material selection and design elements. Also consider the installation site and how field erected tanks may present challenges.

Importance of Cold Resistance

An elevated water tank is at risk of freezing in below zero temperatures, which in turn could leave the community without a reliable water source. A variety of water tank heating methods may be implemented to prevent freezing, including gravity circulation, steam coils, and/or direct steam discharge.

Elevated Water Storage Tank Applications

In addition to municipal water storage, elevated storage tanks offer a reliable solution for a variety of other applications, including:

-

Fire protection

-

Process water

-

Emergency cooling

Elevated Water Storage Tank Maintenance

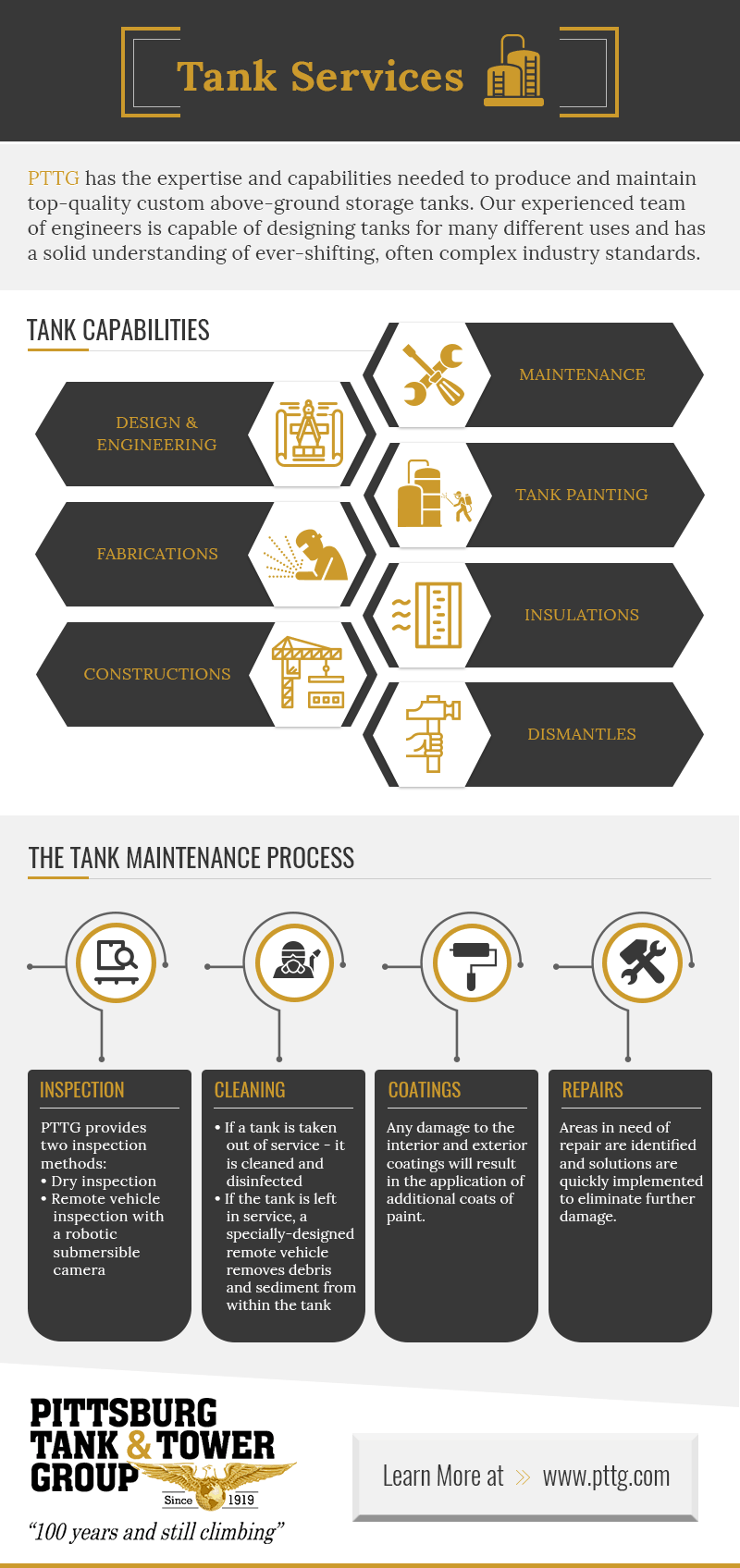

To ensure optimal tank operation and ideal water quality, regular maintenance of elevated storage tanks is critical. Industry standards established by the AWWA and most federal, state, and local regulations recommend inspecting water tanks every 3-5 years.

Inspectors examine the tank’s coating, components, fixtures, surfaces, and foundation to ensure that everything is stable and in good working condition. Any imperfections or irregularities observed during inspection should be repaired in a timely fashion to prevent worsening problems such as leakage, pressure loss, and water quality. Be sure to test your water quality regularly to avoid sediment buildup and potential contamination from loose, leaking, or damaged tank components.

Why Choose PTTG?

Since 1919, Pittsburg Tank & Tower Group has provided durable above-ground storage tanks for municipal and corporate applications. Our state-of-the-art facility and highly knowledgeable staff make us premium tank suppliers, ensuring that we can provide the highest quality storage tanks and large capacity water storage tanks available for any application. In addition to our elevated water tanks, we are pleased to offer an expansive portfolio of storage tank solutions for customers in the energy, chemical, oil and gas, food processing, and paper industries, among many others.

As one of the most experienced water tower companies, we also offer a variety of related services, enabling you to reduce the overall water storage tank cost by using a single vendor. We offer engineering services, custom water tower ladders, and we can also handle even the most precise tank modifications.

If you are looking for a cost-effective solution to your water tank needs, consider taking advantage of our leasing program or utilizing one of our fully refurbished pre-owned tanks. To learn more about our elevated water tank solutions or more information about specific tank specifications, contact our experts today.