Storage tanks and water towers require periodic inspections, cleanings, and maintenance to maintain proper water quality as well as longevity of the equipment. Depending on location, conditions, and type of tank or tower, inspections should be performed every one, three, or five years. Maintenance should be performed based on inspection findings. As a company with a culture focused on safety and customer satisfaction, Pittsburg Tank & Tower Maintenance knows the importance of staying up to date with OSHA, AWWA, NFPA, TCEQ, FM, API, and many other codes.

PTTG offers dry and ROV tank inspection services. As the name implies, dry inspections are conducted when the tank is dry and has been taken out of service. ROV inspections are performed with the tank still in service. Regardless of what method is used, our qualified inspectors will conduct paint mil thickness, ultra-sonic testing for metal thickness, cross hatch testing for adhesion, and test for the presence of lead in paint during each inspection. Fully detailed reports, full of pictures and recommendations will also be sent to the customer. ROV inspections also come with a video of the inspection.

Routine tank inspections help

Operators keep track of their tank’s interior condition, for example, if the interior lining needs replacing. Interior linings deteriorate over time. As the tank heats up and cools down depending on the season, the epoxy becomes brittle, cracks, and flakes off – exposing steel to water. The vapor zone is the area between the high-water line and the tank’s roof. It tends to see a lot of moisture and chlorine vapors. It will deteriorate steel that is not coated extremely fast.

Water tank interiors should be regularly recoated. The lining should also be installed and regularly replaced inside the tank since the water lapping against the tank’s walls will eventually cause it to deteriorate. Pittsburg Tank & Tower Maintenance Co. can install passive cathodic protection in the form of a Zinc disc that sacrifices itself if some type of corrosion occurs. The Zinc discs can be replaced.

Paint fading due to exposure and ultraviolet rays

-

Water tank exteriors should also be recoated regularly. The sun’s ultraviolet rays beat down on a water tank, causing the paint to fade and break down over time. Acidic bird droppings will also eat away at the paint, leaving open spots prone to rusting.

-

Operators can have isolated spots sanded down and touched up with paint. However, if the decay is too advanced, it will require fresh coats of paint. The tank would need to be stripped of its existing coating and repainted with two or three coats of epoxy and NSF epoxy.

-

Tanks should be cleaned out every three or five years, depending on the location, conditions and type of tank. Regular tank cleaning will get rid of sediment and buildup. Would you want to drink out of a water tank that has a foot or more of dirt, mud and other particles sitting at the bottom of it? Probably not, but many tanks will accumulate this much sediment if tank cleaning is not performed regularly.

-

Pittsburg often uses remotely operated underwater vehicles to clean water tanks. This allows the tank to remain in service. ROVs can be used in most cases as long as the sediment is not a foot deep or more. Dry cleanouts demand that the tanks be drained before any cleaning begins.

-

Keeping your tank maintained helps reduce expenses in the long run. Regular inspections and maintenance help keep a storage tank operating for decades or even a century. So, yes, while there is an investment in keeping a tank in good working condition, it’s a lot cheaper than having to buy a new tank or a few new tanks in that same time span.

Types of Water Tank Inspections

Storage tank inspections and maintenance are performed by dry inspection or remote operated vehicle (ROV) inspections.

Dry inspections: Performed while the tank is empty.

We verify the integrity of your tank, including any noncompliance issues, like ultrasonic, mil thickness, lead check, and crosshatch testing. We can also perform vacuum box testing on floors to identify potential leaks.

-

Ultrasonic tests determine the thickness of steel. Various areas of the tank are tested and recorded for each ring of the tank as well as the roof.

-

Mil thickness tests will reveal how well your paint system is holding up.

-

Lead check tests will determine if lead-based paint has been applied to the tank.

-

crosshatch testing is another method used to determine the integrity of your paint system.

-

Vacuum box testing can be performed in dry tank inspections to identify leaks on the tank floor.

Remote vehicle inspections: Performed by robotic submersible cameras, which follow the same basic criteria as our dry inspections without taking the tank out of service.

Cleanouts: ROV or dry cleanouts. ROV cleanouts performed while tank is still in service.

Importance of Storage Tank Maintenance

Storage tank maintenance and water tower maintenance are essential for protecting the performance and longevity of your storage tank.

-

Regular water tank inspection allows for the identification of existing and potential failures, so maintenance and industrial water tank repairs can be performed, limiting ongoing damage. Infiltrations allowing contamination, corrosion, delamination of coatings, and other tank or tower issues are corrected, improving tank or tower performance and reducing costs associated with performing more extensive repairs when inspections are overlooked.

-

Routine cleaning and storage tank maintenance reduces the risks that negatively impact water or other fluid quality, as well as the integrity of the tank. Bacterial growth and sediment build-up are minimized protecting the tank’s interior lining, reducing costs associated with recoating.

-

Overall, storage tank and water tower maintenance will protect your equipment and keep it in service longer. Resolving tank issues as soon as possible eliminates costly repairs when damage becomes more significant and safeguards your water supply. Utilizing professional storage tank maintenance services is an important investment in your business, your equipment, and your bottom line.

Request a Quote for Storage Tank Inspection Today

Keep your storage tank well maintained for improved performance and reduced costs. The team at Pittsburg Tank & Tower Group provides the professional storage tank inspection and water tower inspection services that boost efficiency and keep your equipment in service longer. Please contact us to learn more about how our tank inspection company can benefit your business and equipment.

Tank Inspection

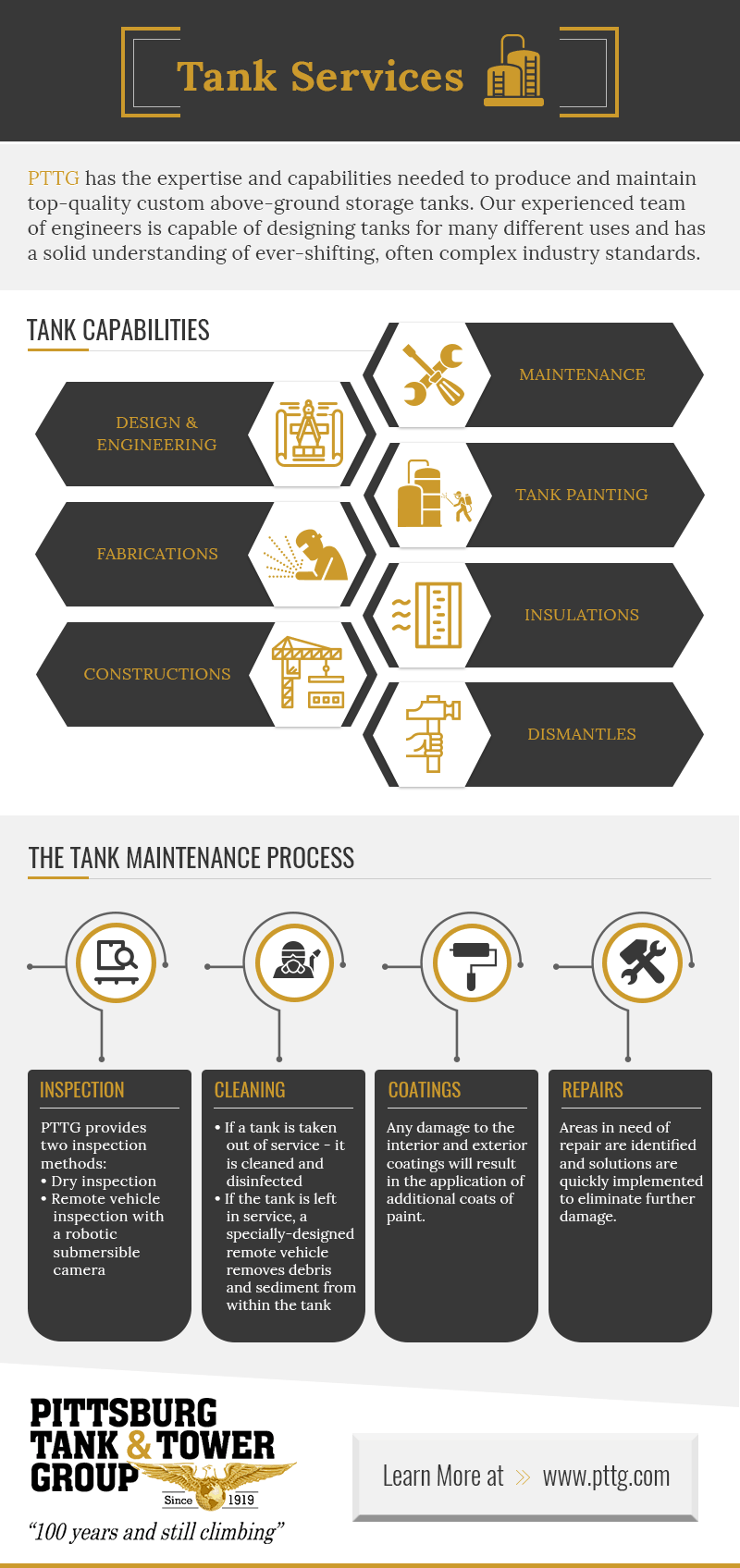

Tank InspectionRegular inspections are mandatory and required at 1, 3 or 5-year intervals depending on the tank’s location and usage. Our detailed inspection reports identify any tank issues, as well as targeted solutions for your needs.

Dry Inspection: We verify the integrity of your tank, including any non-compliance issues, including ultra-sonic, mil thickness, lead check, and cross hatch testing.

Remote Vehicle: Performed by robotic submersible cameras and follow the same basic criteria as our dry inspections without taking the tank out of service.

Cleanout

CleanoutOut of Service: Cleaned and disinfected using AWWA Disinfection Methods.

Coating Restoration

Coating RestorationInterior Linings: From potable water to volatile chemicals, in any structure or environment, PTTG can provide the right lining for your tank.

Exterior Coatings: Protection isn’t the only concern when it comes to the exterior coating of your tank. PTTG also offers the ability to produce different aesthetics for your tank that will not just make it a piece of infrastructure, but an attractive landmark with the use of logos and multiple colors.

Modifications/Repairs

Modifications/RepairsNo job is too small or too large for our repair crews. We specialize in anything from leak repairs to full container replacements.

Specialty Solutions

Specialty SolutionsRegardless of the challenge you face, our team will deliver the solution you need. From utilizing temporary tanks to ease the burden of having your tank out of service to raising, lowering, or relocating existing structures to meet your needs, we have nearly a century of experience in getting the job done right.

Cathodic Protection

Cathodic ProtectionThrough the use of sacrificial anodes, we can offer protection that lasts years. Our passive cathodic protection systems rely on the placement of these sacrificial anodes that act as a proponent of an electrochemical cell which will deteriorate in lieu of the tank structure, prolonging its life. PTTG also offers an alternative style of cathodic protection known as “active” or impressed current cathodic protection. This cathodic protection system utilizes the same principle of the passive system, but has the anodes connected to a DC power source.

Extended Warranty

Extended WarrantyOur extended warranty program is a money saving investment that will allow you to get the most life out of your tank. With annual inspections, biannual clean outs, and scheduled maintenance, you will maximize returns on your capital investment. Warranties include annual inspections, scheduled maintenance, coating restoration, and various other benefits.