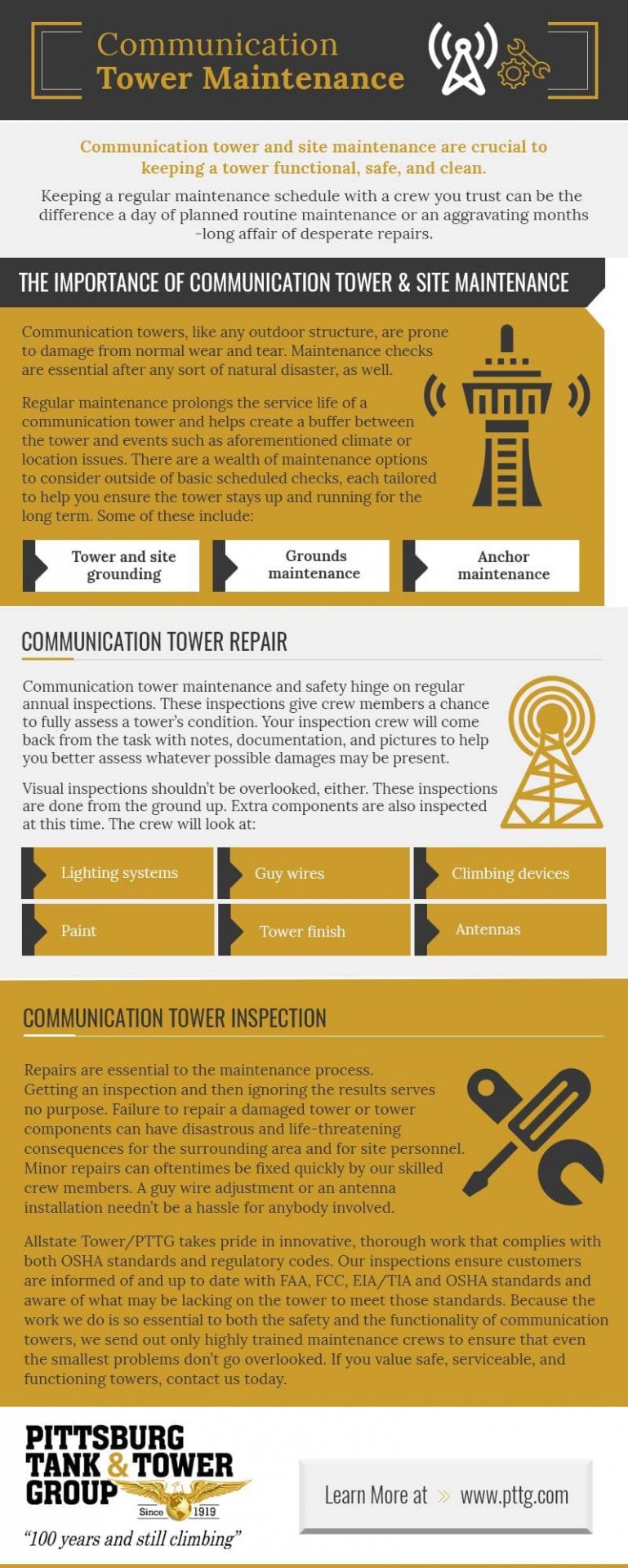

Communication tower and site maintenance are crucial to keeping a tower functional, safe, and clean.

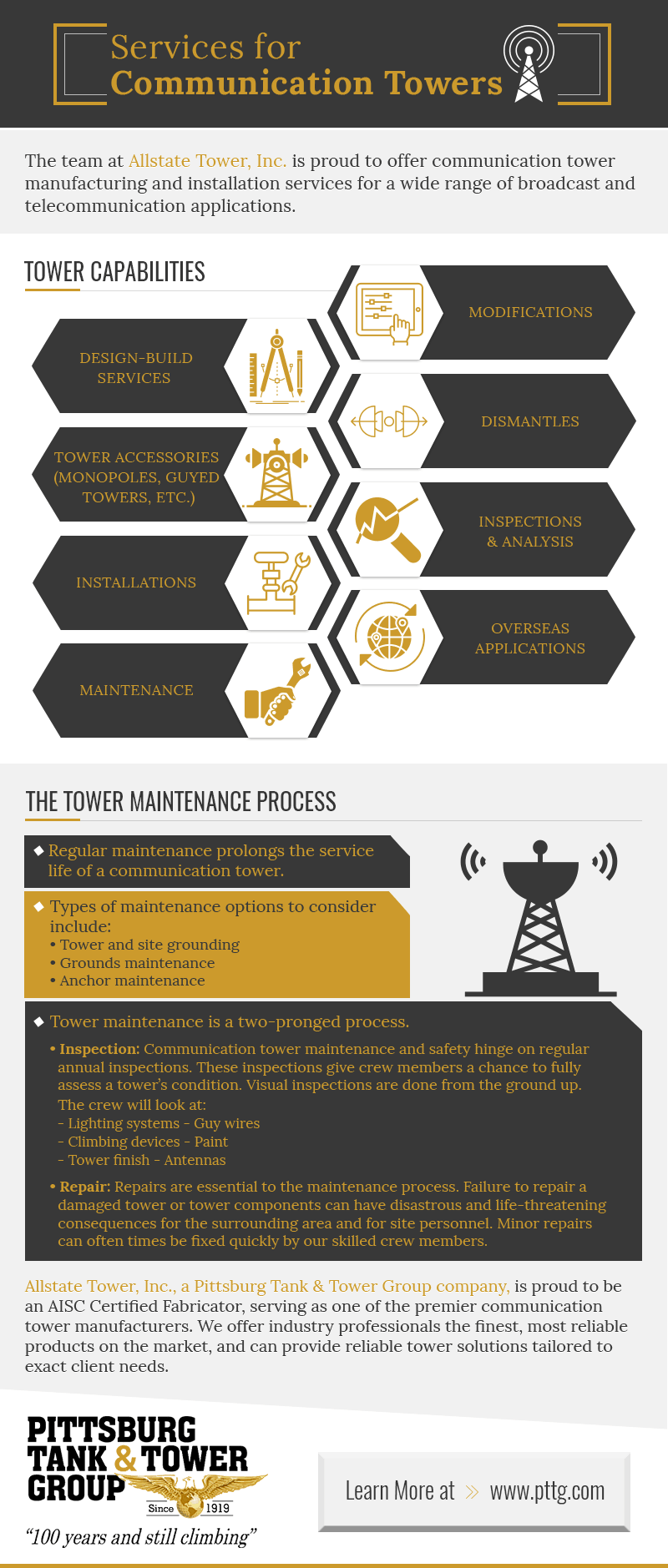

Communication tower maintenance services guarantee that towers remain operational and compliant with necessary safety standards. Their role is critical in preventing unexpected breakdowns and costly repairs. Keeping a regular maintenance schedule with a crew you trust can be the difference a day of planned routine maintenance or an aggravating months-long affair of desperate repairs.

Allstate Tower, a division of Pittsburg Tank & Tower Group, offers maintenance checks and OSHA-compliant safety system installation. If issues with plumb and tension, tower and site grounding, guy wires, or a range of other common and less common issues arise, Allstate Tower can help with those too.

The Importance of Communication Tower & Site Maintenance

Communication towers, like any outdoor structure, are prone to damage from normal wear and tear. This is especially true if those towers are located in areas that frequently experience severe or inclement weather, or are located near coastlines or bodies of water. Maintenance checks are essential after any sort of natural disaster, as well.

Regular maintenance prolongs the service life of a communication tower and helps create a buffer between the tower and events such as aforementioned climate or location issues. There are a wealth of maintenance options to consider outside of basic scheduled checks, each tailored to help you ensure the tower stays up and running for the long term. Some of these include:

-

Tower and site grounding

-

Grounds maintenance

-

Anchor maintenance

Companies that offer communication tower maintenance services can work with client’s specific needs and tailor these inspections and repairs to address site needs. It creates a level of customization to help make sure the tower operates at peak efficiency. Tower maintenance is a two-pronged process. While your maintenance company is responsible for inspection, they also take care of suggesting and completing whatever repairs are deemed necessary to tower safety. Many issues either require immediate repairs or are easy enough to take care of that they can be completed right away. Others may be scheduled to be fixed at a later time, such as the next scheduled maintenance period.

Communication Tower Inspection

Communication tower maintenance and safety hinge on regular annual inspections. These inspections give crew members a chance to fully assess a tower’s condition. Your inspection crew will come back from the task with notes, documentation, and pictures to help you better assess whatever possible damages may be present.

Visual inspections shouldn’t be overlooked, either. These inspections are done from the ground up. Extra components are also inspected at this time. The crew will look at:

-

Lighting systems

-

Guy wires

-

Climbing devices

-

Paint

-

Tower finish

-

Antennas

Thorough inspections mean a greater likelihood of catching issues, and a thorough inspection enables a full service solution. These sorts of inspections often allow for damages to be identified and repairs to be made within the same day.

Communication Tower Repair

Repairs are essential to the maintenance process. Getting an inspection and then ignoring the results serves no purpose. Failure to repair a damaged tower or tower components can have disastrous and life-threatening consequences for the surrounding area and for site personnel. Minor repairs can oftentimes be fixed quickly by our skilled crew members. A guy wire adjustment or an antenna installation needn’t be a hassle for anybody involved.

Allstate Tower/PTTG takes pride in innovative, thorough work that complies with both OSHA standards and regulatory codes. Because the work we do is so essential to both the safety and the functionality of communication towers, we send out only highly trained maintenance crews to ensure that even the smallest problems don’t go overlooked. If you value safe, serviceable, and functioning towers, contact us today.

Antenna and Coax

We offer complete antenna and line maintenance with capabilities that include replacement and installation of panel antennas, omni directional antennas, standard dishes, high-performance dishes, FM Antennas, Yagis, HDTV antennas, and AM folded unipoles/detuning skirts. Our qualified technicians can install any type of heliax, rigid coax, cable downleads, RG cable, elliptical waveguide line that these antennas require. Line sweeping and testing services are also available.

Light Systems

Our crew will perform periodic re-lamping and inspection services of many different types of lighting systems in accordance with FCC/FAA codes to ensure trouble free operations and avoid costly fines. We also offer installation and maintenance services with 24-48 hour emergency response time in most cases.

-

Medium Intensity Strobe Systems

-

Red Incandescent Lighting Systems

-

High-Intensity Strobe Systems

-

Medium Intensity Dual Systems

-

LEDs

Guy Wire Maintenance

Our crews are trained to properly maintain or replace insulated rods, egg/johnny ball insulators, insulated guy wires, guy coating and injection services. Special coatings include, but are not limited to:

-

Insulated Rods/Guys

-

Insulators

-

Prelube 19

-

Dyna-guard Blue

-

Zinc-rich Paints

-

No-Oxide Special A Grease

-

Ice Phobic

Tower/Coax Painting

Towers must remain in compliance with current FCC and FAA standards and regulations for day marking. All of our manufactured towers are galvanized and receive one top coat of industrial acrylic enamel orange and white paint mixed to comply with current Federal Specifications 595-A when specified. Our crews are also experienced and qualified to handle:

-

Polyurethane

-

Epoxy Mastic

-

Keeler & Long 4404

-

Custom Paint Applications

-

Lead Abatement

Plumb and Tension

Guy wires stretch over time and during adverse weather conditions. We routinely plumb and tension in accordance with EIA/TIA 222.

Anchors, Foundations, and Cathodic Protection

We can safely repair or replace eroded base piers and modify tower and anchor foundations based on structural analysis by applying good practices. We can replace many different types of damaged, corroded or undersized guy anchor systems and anchor bolts in accordance with EIA/TIA 222 standards.

We also offer a complete line of cathodic protection systems to offer protection from undetected corrosion of guy anchors below grade.

-

Anchor Replacement

-

Helical Type Anchors

-

Dead-Man Anchors

-

Caisson Type Anchors

-

Elevated Anchors

-

Rock Anchor Systems

-

Cathodic Protection Systems

Tower Accessories

-

Ice Shields – 2? Model, 4? Model, 6? Model, 8? Model

-

Side Arms – 3? Model, 2? Model, 6? Model

-

Dish Mounts – Universal Dish Mount Assembly, Universal Dish Mount Assembly – Large, Straight Face

-

Mount Mounted Dish Mount, Tapered Face Mount Mounted Dish Mount, Light Duty Dish Mount

-

Sector Frames – Sector Mount Kit, 6 Pipe Kit, 12 Pipe Kit, Sector Mount Adapter

-

Custom Mounts – Pinwheel Mount

-

W/G Bridges – 5? Model, 10? Model, 1 Layer Hanger, 2 Layer Hanger, 3 Layer Hanger

-

W/G Ladders – Waveguide Ladder Kit

-

Climbing – Clip On Climbing Ladder, Step Bolts

-

Safety Climb Devices

-

Anti-Climb Devices – Anti Climb Model 1, Anti Climb Model 2

-

Cathodic Protection

-

Non-Penetrating Roof Mounts

-

Beacon Mounts – Universal Beacon Mount, Dual Beacon Mounts, Beacon Mount Extension

-

Torque Arms

-

Guy Pull-Off Lugs – Guy Model

-

Guy Insulators

-

Base Insulators

-

Strain Insulators

-

Lightning Rods/Extensions – 5? Extension Model

-

Air Terminals

-

Lightning Dissipaters Systems

-

Grounding Materials – Guyed, Self-Supporting and Monopole

-

Modification Materials – Guyed, SS and Monopole

-

Water tank – corrals and coax management components