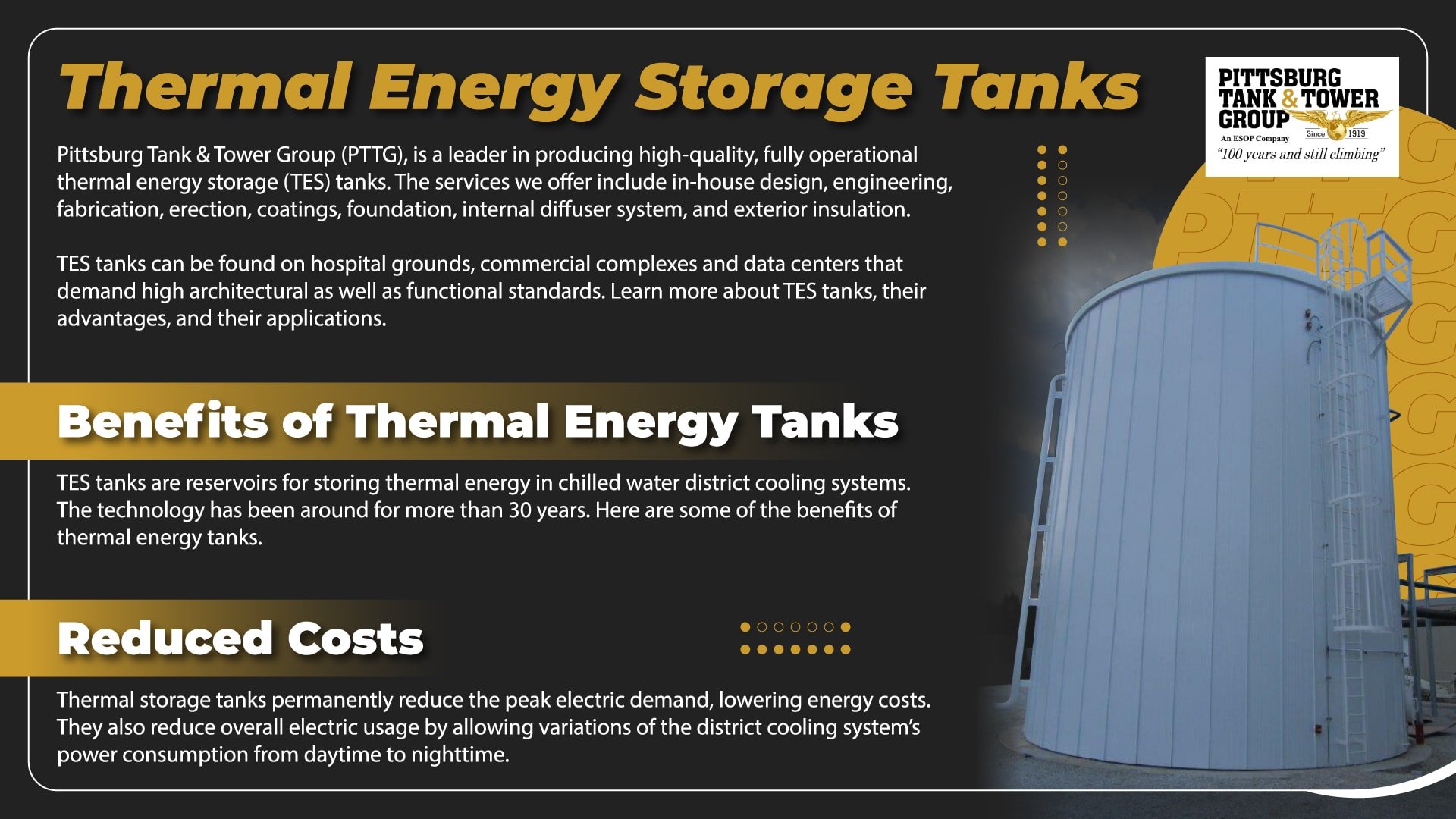

Pittsburg Tank & Tower Group (PTTG), is a leader in producing high-quality, fully operational thermal energy storage (TES) tanks. The services we offer include in-house design, engineering, fabrication, erection, coatings, foundation, internal diffuser system, and exterior insulation. Thermal energy storage tanks play a vital role in balancing energy supply and demand. They can help improve the efficiency of renewable energy systems by storing surplus energy for later use.

TES tanks can be found on hospital grounds, commercial complexes and data centers that demand high architectural as well as functional standards. Learn more about TES tanks, their advantages, and their applications.

Benefits of Thermal Energy Tanks

Thermal storage tanks are reservoirs for storing thermal energy in chilled water district cooling systems. The technology has been around for more than 30 years. Here are some of the benefits of thermal energy tanks.

Storage Capacity

TES tanks can hold 35,000 to 10 million gallons, with varying ton-hours of capacity depending on the needs of the system. Tanks are also available in varying design options to suit different client needs and site restrictions.

Mission-Critical Security

Data centers require uninterrupted cooling, and TES tanks—functioning like batteries of cold water—meet these demands. When the chiller equipment goes offline either intentionally or unintentionally, cold water storage tanks can continue to provide cooling capabilities.

Improved Efficiency

TES tanks take advantage of off-peak energy rates by cooling water during these hours (usually overnight) and using it during high-rate hours (usually daytime). Water has better thermal transfer properties than air, making air conditioning systems more efficient and economical.

Capacity Expansion

Places with higher cooling loads can use a welded steel chilled water storage tank to avoid the costs of installing a new cooling tower, chiller, and pump. The tanks also increase the existing cooling system’s efficiency and longevity by maximizing plant uptime and allowing for more regular equipment maintenance.

Reduced Costs

Thermal storage tanks permanently reduce the peak electric demand, lowering energy costs. They also reduce overall electric usage by allowing variations of the district cooling system’s power consumption from daytime to nighttime.

How Thermal Energy Storage Works

Diffusers at the top and bottom of a TES tank let in and release water. Warm water enters and exits from the top, while cool, denser water enters and exits from the bottom. In the middle is a thermocline—a narrow transition layer of water.

When the distribution phase is in its final stages, most of the water in the tank is warm. During recharge or cooling, the warm water exits via the top diffuser to reach the cooling plant. It cycles back into the tank via the bottom diffuser as chilled water, ready for use in the cooling system.

Thermal energy storage tanks often feature insulation to minimize energy loss. We can use durable materials like reinforced steel to make sure our tanks have long lifespans and offer reliable performance.

Industries Served

The main uses for TES tanks are in turbine inlet cooling systems, chilled water cooling systems, and mission-critical applications such as brownouts and power outages. These are the common settings and industries that rely on TES tanks for cooling:

-

Industrial/commercial buildings

-

Schools and universities

-

Airports

-

Hospitals

-

Military

-

Government

-

Natural gas power plants

-

Data centers

-

Banks

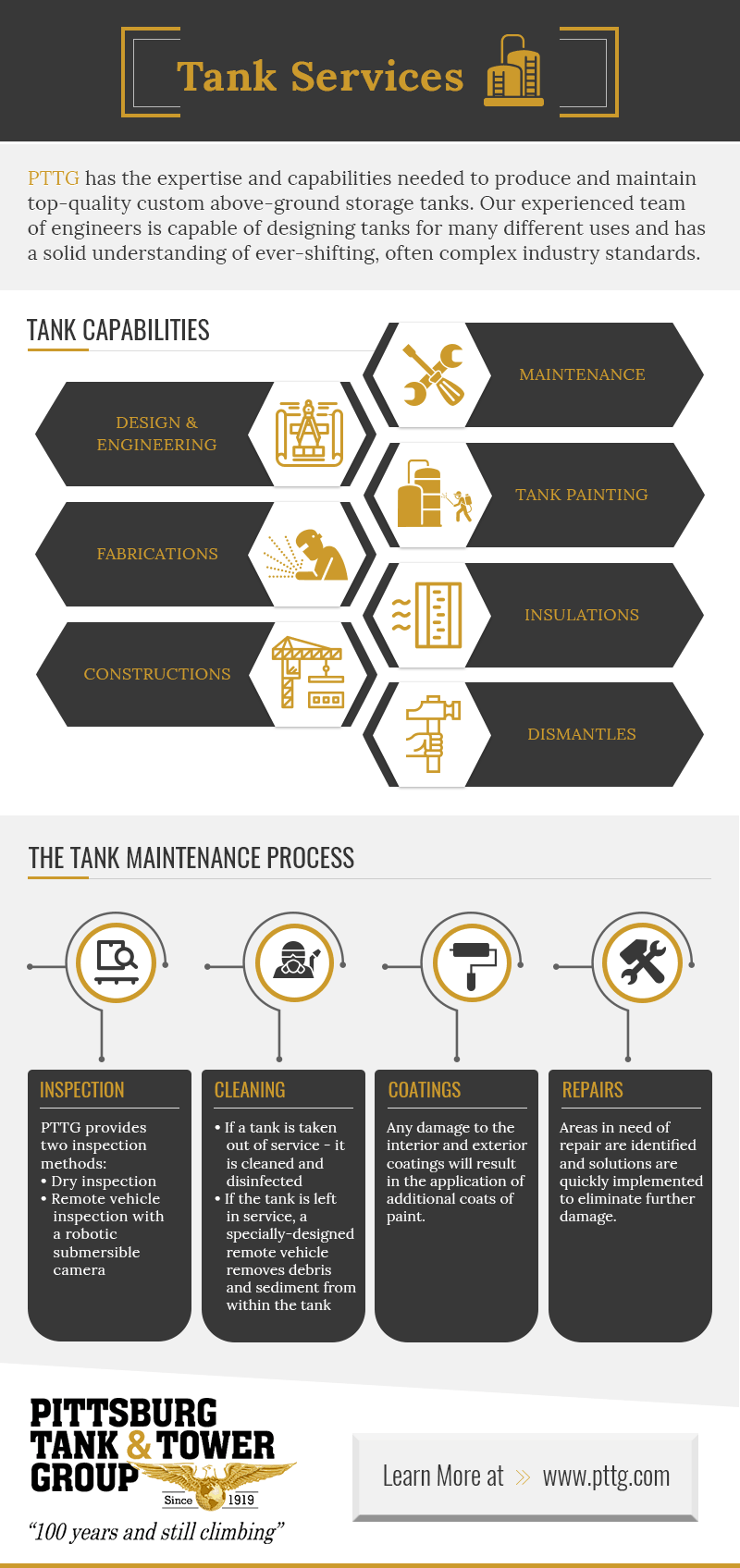

Why Work With PTTG?

If you need reliable thermal energy storage tanks, PTTG is your go-to thermal storage tank supplier. Customers from diverse industries—including energy, oil and gas, and food processing—depend on our reliable storage tank solutions to meet their needs. We have a highly trained team of experts and an ultra-modern facility to design, manufacture, and deliver top-notch storage tanks for almost any application.

We are expert TES tank solution providers because:

-

We are a full-service tank supplier.

-

We can build tanks that can hold up to 10 million gallons.

-

We customize sizing and other client specifications without restrictions.

-

We make both closed and open loop designs.

-

Multiple TES tanks by PTTG have been in use since 1995.

-

We use stainless steel, carbon steel, or polyvinyl chloride (PVC) internal pipe diffusers.

-

We provide turnkey installations, from the internal diffusers to coatings to insulation.

-

We can accommodate special design considerations depending on flow rates, ton-hour storage, and other service requirements.